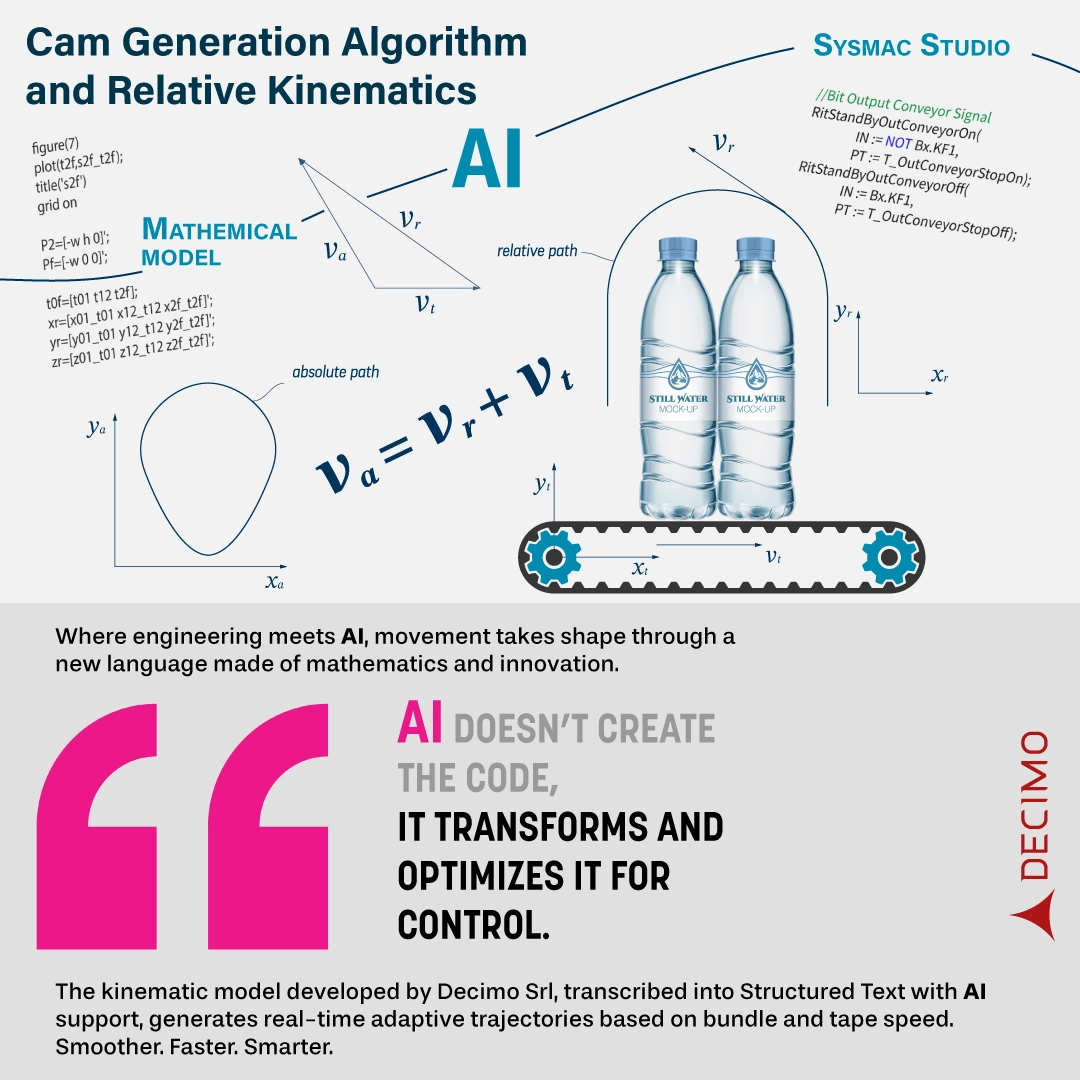

XHE v3.0 Electronic Handle Applicator – Advanced Software Development with AI Support and Precision Motion Control by Decimo Srl

High performance, servo-assisted architecture and optimized trajectory control: the new XHE integrates AI to optimize the adhesive handle application process.

Introduction

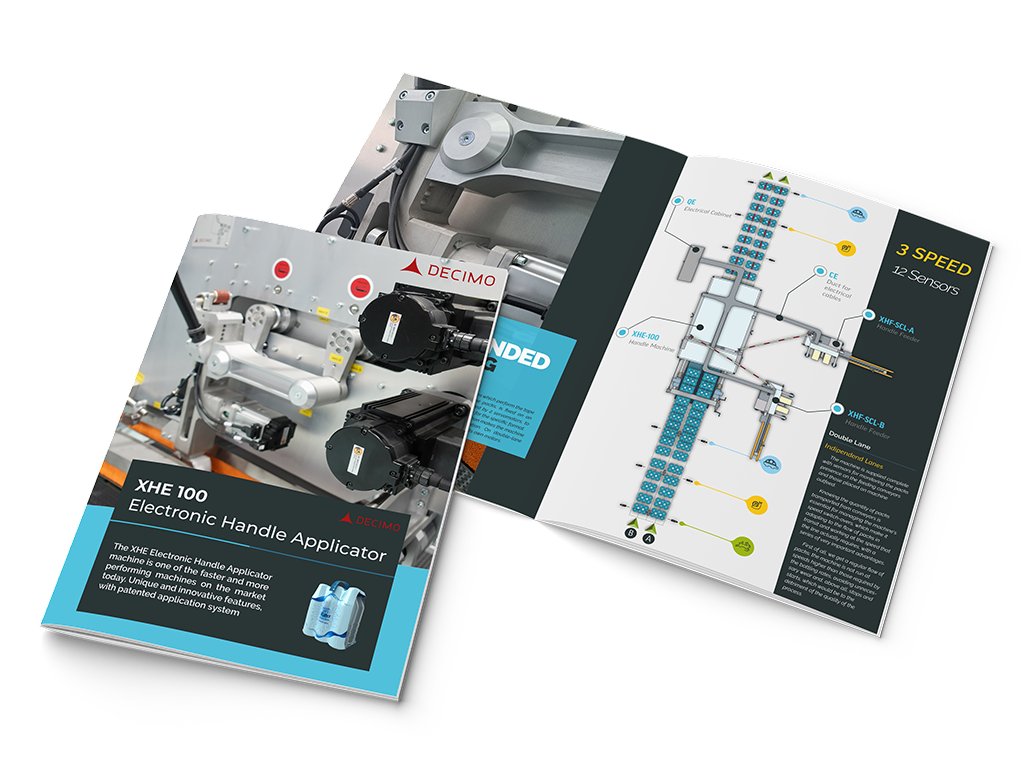

The XHE electronic handle applicator, developed by Decimo Srl, is a modern and versatile solution for applying adhesive handles to multipacks. It combines automation, motion control, and a patented applicator arm to ensure smooth, precise, and repeatable dynamics even at high speed, with simplified setup and enhanced operational safety.

AI doesn't write our code, it transforms and optimizes it for control.

System Architecture and Kinematic Model

From May 7 to 10, 2024, Decimo Srl participated in Hispack, one of the leading European packaging trade fairs held at Fira de Barcelona. The event was an important opportunity to present our innovative technologies to an international audience of professionals and decision-makers.

Algorithm Evolution: from Simulation to Structured Text

The algorithm was initially validated through simulations using one of the world’s most recognized scientific computing tools and supported by ChatGPT Team. It was then completely rewritten in Structured Text (ST) for the Sysmac Studio automation environment. The translation and optimization were assisted by AI models, enabling automatic generation of motion trajectories based on a single operational parameter: bundle width.

Key Benefits Introduced:

- Elimination of format-specific preloaded cams

- Increased adaptability to production variability

- Code optimization and simplified logic

- Reduced PLC scan time

Axis Control, Synchronization and Feedback

All movements are synchronized in real time via EtherCAT bus. Closed-loop vector inverters with encoders provide precise feedback to the controller, ensuring repeatable stops and dynamic position correction of the gripper. This keeps the handle centered even during speed variations, ensuring fluid movement with long acceleration ramps and longer-lasting components.

Line Integration and Adaptive Flow Control

Since version v2.0, a dynamic flow management system has been introduced to automatically adjust production speed on three levels (low, medium, high) based on line conditions. It can receive signals both upstream and downstream, adjusting speed in real time. This improves continuity, reduces stoppages, and handles load variations more effectively.

HMI – Human-Machine Interface

The XHE’s HMI is designed to be practical and user-friendly, with software and manuals developed by a specialized team and available in various formats. The dual-lane version includes 2 HMI displays, one per side, eliminating bulky arms and reducing cable damage risk. Even if one display fails, the other ensures continuous operation. The layout resembles smartphone apps, with 7" standard and optional 10"+ models. The manual, accessible online and constantly updated, includes quick guides for format change and axis referencing.

Main Options

The XHE enables quick format change with three main adjustable elements:

- Infeed side guides

- Application head width

- Application head height

These adjustments are available in manual (via cranks and HMI), semi-automatic (via buttons), or fully automatic (motorized with encoders) modes, allowing fast, interruption-free format changes.

Version Evolution

XHE v1.0

- Cams calculated in simulation software and loaded manually

- Single HMI and rotating button panel

- Input-only flow control

- No internal lighting

- Mechanical safety switches

XHE v2.0

- Closed-loop vector inverters with encoders

- Dual-side HMIs

- LED internal lighting

- Bidirectional speed control

- Enhanced flexibility

XHE v3.0

- Automatic cam generation

- Simplified configuration

- Non-contact LED sensors

- Optimized software

Conclusions

The XHE v3.0 is a mature and innovative solution for automated adhesive handle application. It combines physical modeling, advanced programming, and industrial automation, setting a benchmark in integrating AI into motion control processes.

Reference Text: Bruno Siciliano, Lorenzo Sciavicco, Luigi Villani, Giuseppe Oriolo, Robotics – Modelling, Planning and Control, Third Edition, McGraw-Hill.

Additional Note: The translation and optimization of the algorithm into Structured Text (ST) were carried out using ChatGPT Team by OpenAI and supported by the Sysmac Studio automation environment by Omron.

Author: Eng. Vincenzo Ripa – Decimo Srl